The team (a collaboration between SISSA, the International Centre for Theoretical Physics "Abdus Salam" ICTP of Trieste, the Italian National Research Council CNR, and the Swiss Federal Laboratories for Materials Science and Technology) conducted a theoretical, simulation-based study.

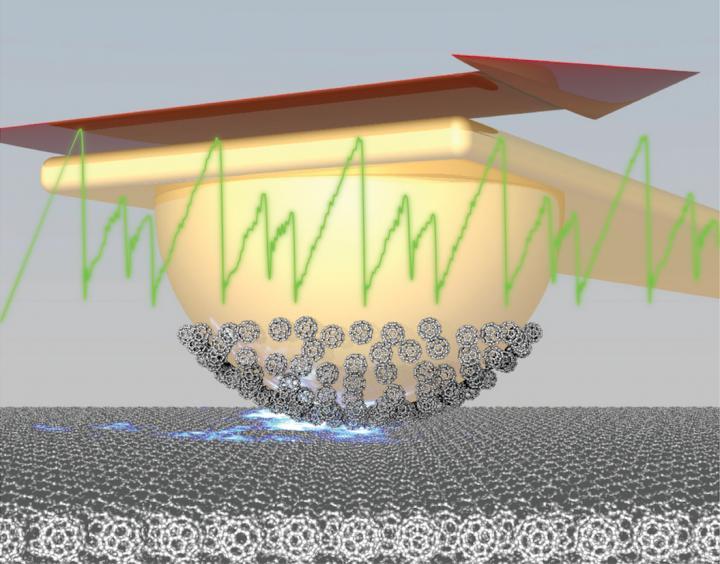

"We simulated the tiny tip of an electron microscope bearing a C60 flake, which was dragged over a surface also made of C60", explains Vanossi. "We discovered that when the flake was attached in such a way that it couldn't rotate the friction did not decrease, even if we raised the temperature to above 260° K. It's as if the bearings making up the flake interlocked with the substrate, with no nano-bearing effect. However, when the flake was free to rotate there was a dramatic drop in friction and the flake could slide over the surface far more smoothly". But here the drop in friction is not due to the ball bearing effect, but to the change in contact geometry.

The two states therefore reproduce the results of the two experiments. "Our data faithfully reflect the empirical observations", concludes Tosatti. "This of course does not bode well for the future use of fullerite to reduce friction at the nanoscale, in that the nanobearing function is not confirmed, but it does finally shed light on the physics of this problem".

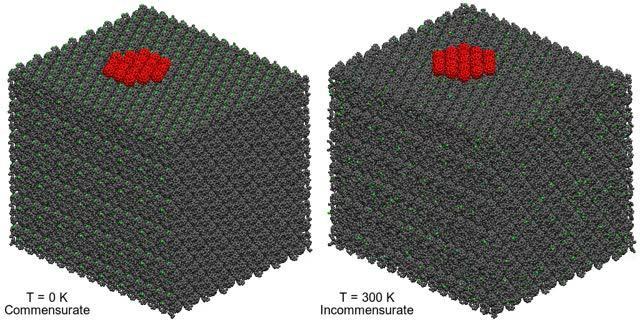

The video compares the two sliding states of the C60 flake attached to the tip of the microscope: a) commensurate state at low temperature where the C60 do not rotate and the system shows stick-slip (high) friction and b) incommensurate state at high temperature where the C60 rotate and the flake moves more smoothly (low friction). The green points simply colour one of the 60 atoms making up the C60 molecules to better highlight the absence/presence of rotation below/above the critical temperature.

(Photo Credit: SISSA)

This is an image of the system.

(Photo Credit: SISSA)